|

|

|||||

|

The Irish Bouzouki: A Mandolin on Steroids by Graham McDonald Graham McDonald makes Irish bouzoukis of several types: 4-course, 5-course, flattop, and archtop. In this issue he runs down the history of the Irish bouzouki and shows us how he builds them. Interestingly, he makes the archtops out of flat pieces of wood. How does he do it? Plastic woven bags. |

|||||

|

Meet the Maker: David King by Jonathon Peterson Meet David King in this issue. Somehow, he got from being a kid in a strictly classical music family to making and playing electric basses, by way of a “folkschool” in Denmark. You just never know. |

|||||

|

Arched Plate Carving, Part Two: Graduating the Top Plate and Cutting the f-Holes by Chris Burt Is Chris Burt eating a molasses cookie while he listens to the roar of the surf in a large shell? Nope, he's finding the tap tone of a mandolin back. This is Part Two of his series on carving arched plates. |

|||||

|

Controlling Classical Guitar Neck Angle by Rodney Stedall Rodney Stedall shows us how to calculate the neck set angle we want in a classical guitar, and then lock that in while the back is glued. |

|||||

|

Meet the Maker: Gregory Byers by Woodley White Attending a seminar with Jose Romanillos at the Toronto classic guitar festival in 1981 set Gregory Byers on a path of excellence and innovation. Meet him in this issue. |

|||||

|

Octet 2005: First Convention of the New Violin Family Association by Alan Carruth The New Violin Family, also known as the Violin Octet, has been under development for fifty years. Recently, the first-ever New Violin Family convention was held in Ithaca, New York. Our man Al Carruth attended and gives us the rundown. The photo shows physicist Oliver Rodgers. |

|||||

|

Resurrecting the Family Guitar by John Calkin It's a Le Domino Big Boy, a cheap old tenor guitar with way-cool decals. It had done a lot of falling apart since the '30s, so John Calkin did a quick-and-dirty resurrection, in line with its lack of monetary value. |

|||||

|

The Never-Ending Barber Chair Workbench by Michael Sanden What kind of lutherie workbench has a stick shift? One that is made out of a barber chair! Swedish luthier Michael Sanden was a barber in a former life, and first reported this interesting idea in 1987. He recently overhauled it to meet his current needs. |

|||||

| The Metaphysics of the Guitar by Ervin Somogyi If a simple formulation of wooden parts was all it took to make a guitar there would be no small shops and no handbuilders. The factories would get it right and their efficiency would rule out the little guys. But the factories don’t, and the little guys haven’t been. Somogyi takes a shot at explaining why this is so. |

||||||

|

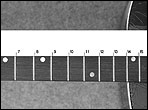

Gibson Used Three Different 24 3/4" Scale Lengths

by Dan Erlewine and Don MacRostie with Tim Shaw See how those little tick marks don't line up with the frets? That's because Gibson has used three different 24.75" scales over the last several decades. It can be a problem. Dan Erlewine and Don MacRostie researched the matter in detail. |

|||||

|

Product Review by Harry Fleishman Like I was saying, those mismatching Gibson scales can be a problem, especially when you go to manufacture fret rules. Harry Fleishman reviews the new, improved fret rules from Stewart-MacDonald. That's Dan Erlewine in the photo. |

|||||

|

It Worked for Me by John Hagen Here's a jig by John Hagen for fitting braces to arched plates. It holds the brace in position while you pull a strip of cloth abrasive through. |

|||||

Web Extras |

||||||