|

|

|||||

|

In Memoriam: Mario Martello by Richard Johnston Mario Martello was a busy and well-liked guitar repairman in the San Francisco area for over forty years. Here's an affectionate eulogy by Richard Johnston. Read his memoriam. |

|||||

|

Low-Tech Prototyping Jigs and Methods by Tim Shaw Tim Shaw used to make prototypes, custom instruments, and artist models for Gibson. Nowadays, he does basically the same thing in his role as Principal Engineer at Fender. He spoke at the 2006 GAL Convention about quickly setting up low-tech tooling for flattop guitar prototypes. Click to see his workshop. |

|||||

|

Meet the Maker: Chris Jenkins by Steve Kinnaird Chris Jenkins makes his visually distinctive guitars at night. That's because he's busy during the day working as a veterinarian. Here's a “Meet the Maker” interview by fellow Texan Steve Kinnaird. Click to see Chris and his son Jeremy at the 2006 GAL Convention. |

|||||

|

Making a Brass Plane from his 2004 Convention workshop by Ken Altman Bowmaker Ken Altman guided several luthiers through the process of making a small brass plane in a hands-on workshop at our 2004 GAL Convention. Here's a step-by-step pictorial of cutting out, soldering, and shaping a lovely and practical tool. |

|||||

|

Mending a Bomber by John Calkin John Calkin steps us through the repair of a super-ugly top crack on an older Gibson B-25. |

|||||

|

The Trio Romantico and the Requinto by Fred Casey Fred Casey gives us an intro to the music and structure of the Mexican requinto, the treble member of the guitar family. The article includes a reduced image of GAL Instrument Plan #54. |

|||||

|

Meet the Maker: Dmitry Zhevlakov by Federico Sheppard Dmitry Zhevlakov's grandfather began making guitars and specializing in intricate marquetry work after WWII. As old barriers continue to break down, Dmitry is able to sell his guitars and elaborate rosettes to customers in may parts of the world from his small apartment workshop in Tula, Russia. |

|||||

|

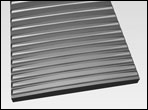

Jim Norris' Lattice Bracing by Brent Benfield Shortly before he passed away, classic guitar pioneer Jim Norris showed Brent Benfield how he built his distinctive lattice-braced guitars. Brent shows us photos of Jim's process, and then moves on to his own interpretation of the design. See a eulogy to Jim Norris by R.E. Brune here. Click to see Brent's version of the braced soundboard. |

|||||

|

Aluminum Sonatas: A Brief History of Aluminum String Instruments by James Condino Did you know that string instruments made entirely or mostly of aluminum have been manufactured for well over a century? James Condino gives us the rundown and takes a detailed look at a violin, a mandolin, and two different makes of double bass. |

|||||

|

Optimizing Playing Surface Geometry by R.M. Mottola Before you ask, I'll go ahead and tell you that it is a computer-generated image of an extremely short-scale cylindrical fretboard which has been filed such that the fret surfaces form a section of a cone. That is, it's a multi-radius fret job on a constant-radius fretboard. R.M. Mottola tells you how, and indeed why, to do it. |

|||||

|

The Chanlynn Deflection Machine by John Calkin At Huss & Dalton, they don't measure the tap tones of the soundboards they make. But they do measure the deflection of each and every one. For this purpose they use a professionally machined jig to support the top and apply a constant weight to given point, plus measure the deflection at that point. |

|||||

|

It Worked for Me by Harry Fleishman, Peter True, Harry Tomita, and Glenn Uhler Talk about cheap and easy. Here's a clamping device made from a plastic bag and a cast-off refrigerator pump. Just one of five helpful hints in this issue's “It Worked for Me” column. |

|||||

Web Extras |

||||||